POLOS 싱글 웨이퍼 스핀코터 Spincoater Main

미래형 고성능 스핀코터? |

|---|

고성능 , 다기능, 고정밀, 고신뢰성 스핀코터. |

|

모든작업 을 콘트롤 가능한 터치스크린 패널 manufactured in Germany. |

|---|

Clear view of your process

Polos 스핀커터는 R&D 용으로 특별히 설계된 스핀코터 입니다. 4" 프로그램용 디스플레이에서 여러작업을 콘트롤 가능합니다. MEMS, Semi-may require mask cleaning, or a coating step conductor, PV, Microfluidics field, 등등 POLOS 싱글 웨이퍼 스핀코터는수많은 응용작업이 가능합니다. cleaning, rinse/dry, coating, developing and etching. USB 소켓 장착 unlimited메모리 및 스텝 기능 독일제 디지털 서보모터 장착으로 최고의 정밀도 및 신뢰성 요하는 작업 가능. α-crystalline NPP-H 사용으로 일반 NPP보다 100C에서 2배이상의 강도 및 내구성 ,내충격성보유. |

|---|

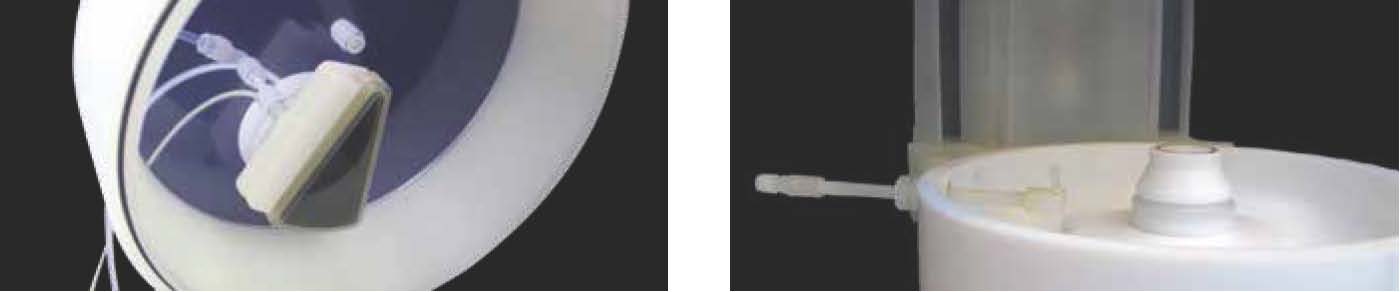

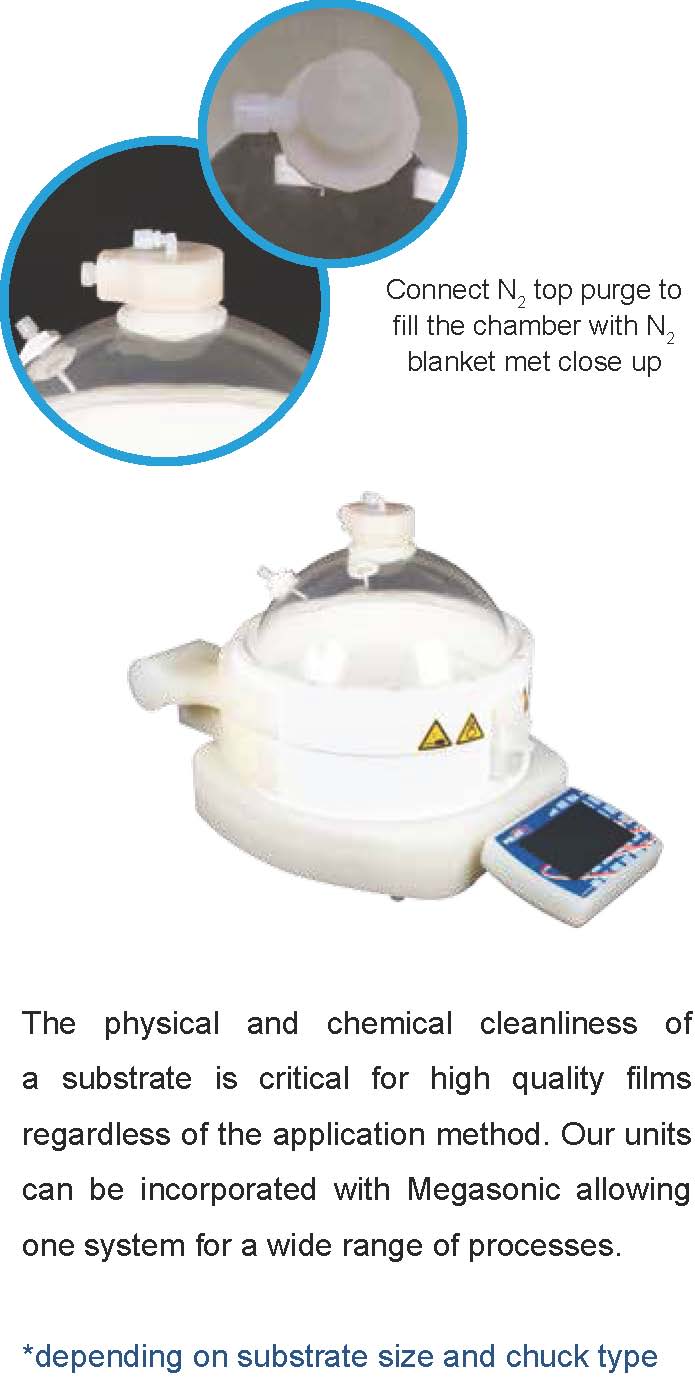

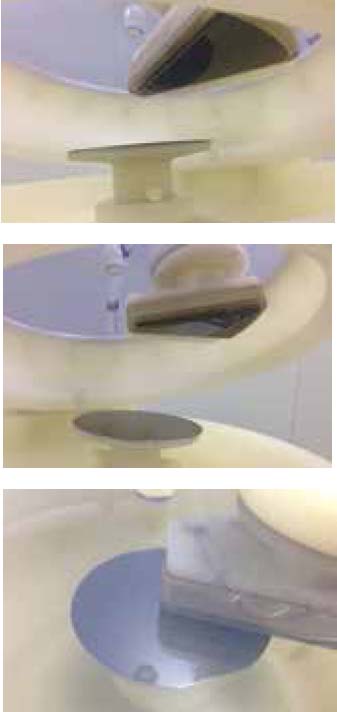

스핀코터 특징:고속 가속 기능 :up to 0 - 12,000rpm in 0.3 sec. between speed and acceleration Without line break 최대 가속도 :30,000rpm/sec 분리 가능한 터치스크린 콘트롤 패널 - 글로브박스 (glove box)내 설치시 유리. 회전 및 역회전 기능:“puddle” develop and/or etch. Full-Engineering Plastics only, high quality seamless fabrication. 세이프티 록 장착. N2 퍼지포트 장착 :Syringe Holder & Diffuser for N2 외부 관찰 가능한 강화 Glass cover장착 :

depending on substrate size and chuck type |

Benefits

Where the application requires PTFE, we use TFM1600 material, superior for use with chemicals above standard PTFE, with a much higher material surface density than standard PTFE,

thus significantly lower “Memory Capability” for absorbing contamination from Chemicals.

Liners are available in PET (Polyethylenterephthalat), 0.5mm thick, transparent, antistatic (108 - 1010 Ω) to prevent possible build-up of static charge in the chamber.

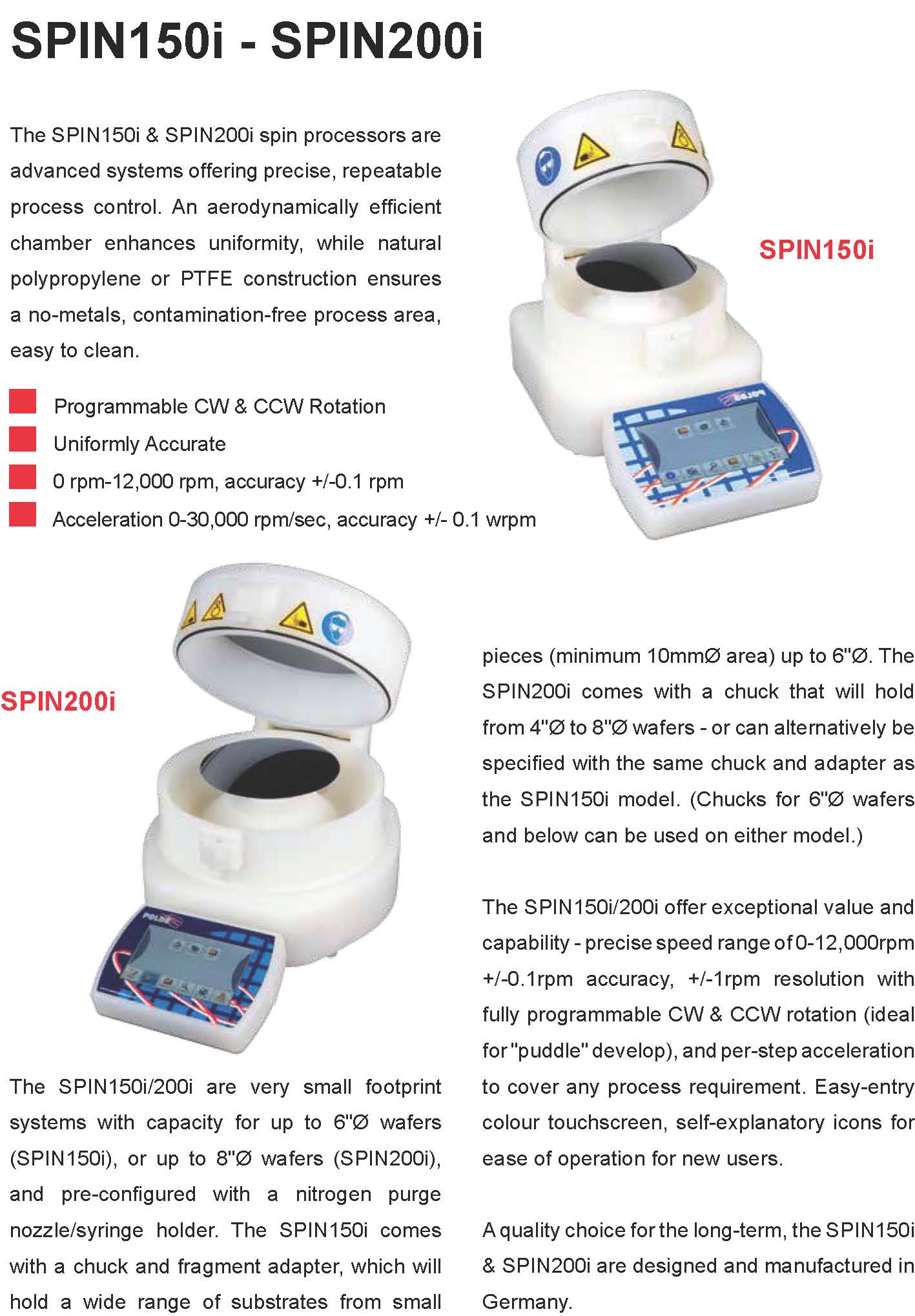

SPIN150i - SPIN200i 스핀코터

| Specifications | SPIN150i | SPIN200i |

|---|---|---|

프로그램수: 스텝: 회전수: 정밀도: 회전방향: |

Unlimited Unlimited 0-12,000 rpm +/-1rpm steps ± 0.1 rpm 정회전,역회전 , Puddle |

Unlimited Unlimited 0-12,000 rpm +/-1rpm steps ± 0.1 rpm 정회전,역회전 , Puddle |

| 최대 가속도:Ramp up down가능 시간 설정 |

30,000 rpm/sec Unlimited , ± 0.1 seconds steps |

30,000 rpm/sec Unlimited, ± 0.1 seconds steps |

| Free programmable outputs: |

3 pcs, relays, nominal switching capacity 0.5A /125 VAC - 0.3A / 60DC |

3 pcs, relays, nominal switching capacity 0,5 A /125 VAC - 0.3A / 60VDC |

시스템 본체 재질: 챔버 재질l: |

Natural Polypropylene (NPP) Natural Polypropylene (NPP) or High Chemical Resistant PTFE (TFM) |

Natural Polypropylene (NPP) Natural Polypropylene (NPP) or High Chemical Resistant PTFE (TFM) |

Interface: External connection: |

Detachable, full-size

touchscreen, glove-friendly, IP52, chemical resistant 1 USB Port in the controller |

Detachable, full-size touchscreen, glove-friendly, IP52, chemical resistant 1 USB Port in the controller |

최대시료 사이즈

:

Max. process chamber diameter: |

160mm round or 4인치 x 4인치 square |

260 mm round or 6인치 x 6인치 square |

| Dimension (desktop version): Shipping weight: Shipping dimension: Requirements Voltage: Power consumption: Max. current: Vacuum: Motor purge gas: Drain connection: |

202 mm 274 (w) x 250 (h) x 451 (d) mm 14 kgs 600 x 380 x 360 mm 100 - 120 VAC / 200 - 240 VAC 50/60 Hz (auto select) Max. 500 W 5A / 2,5A -65 kPa (-19 inchHg), > 80 lpm Tube OD Ø8mm 20 - 50 kPa, 2-5 l/min, Tube OD Ø 6mm 1” M-NPT |

302 mm 380 (w) x 307 (h) x 559 (d) mm 20 kgs 680 x 580 x 480 mm 100 - 120 VAC / 200 - 240 VAC 50/60 Hz (auto select) Max. 500 W 5A / 2,5A -65 kPa (-19 inchHg), > 80 lpm Tube OD Ø8mm 20 - 50 kPa, 2-5 l/min, Tube OD Ø 6mm 1” M-NPT |

Measured without substrate, limitations may apply depending on chuck used and substrate specification

For our spin processors and chucks we use NPP-H with α-crystalline properties..

Options SPIN150i/SPIN200i 스핀코터

|

|

|

|

|---|---|---|---|

|

|

|

|

POLOS Advanced 200 - 300 - 450 스핀코터

|

300mm 300mm |

|---|---|

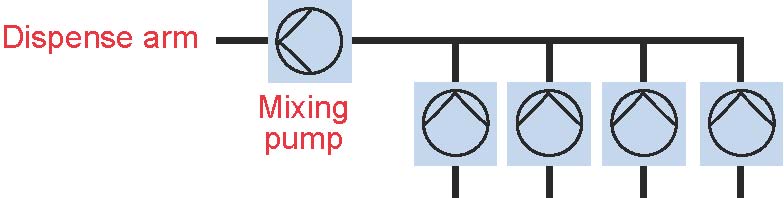

Polos Advanced series는 디스펜싱 장치를 추가 하는데 좀더 편리합니다. |

Automatic Sequential or Parallel Chemical Dispense Up to 6 spray nozzles Each programmable independently Dispense Vessel (DV), DI Water or N2 |

Specifications POLOS Advanced 스핀코터

| Specifications | POLOS 200 Advanced 스핀코터 | POLOS 300 Advanced 스핀코터 |

|---|---|---|

프로그램수: 스텝: 회전수: 정밀도: 회전방향: 최대 가속도:Ramp up down가능 시간 설정 |

Unlimited Unlimited 1 - 12,000 rpm ± 1rpm steps ± 0.1 rpm Clockwise, Counter clockwise and Puddle 30,000 rpm/sec unlimited |

Unlimited Unlimited 1 - 12,000 rpm ± 1rpm steps ± 0.1 rpm Clockwise, Counter clockwise and Puddle 30,000 rpm/sec unlimited |

Free programmable outputs: |

3 dry relays as standard Up to 16 digital input, 16 digital output, 4 analog input, 4 analog output (with optional IO modules) |

3 dry relays as standard Up to 16 digital input, 16 digital output, 4 analog input, 4 analog output (with optional IO modules) |

| 시스템 본체 재질: 챔버 재질l: |

Natural Polypropylene (NPP) Natural Polypropylene (NPP) or High Chemical Resistant PTFE (TFM) |

Natural Polypropylene (NPP) Natural Polypropylene (NPP) or High Chemical Resistant PTFE (TFM) |

Interface: External connection: |

Detachable, full-size touchscreen, glove-friendly, IP52, chemical resistant 1 USB Port in the controller |

Detachable, full-size touchscreen, glove-friendly, IP52, chemical resistant 1 USB Port in the controller |

최대시료 사이즈

: Max. process chamber diameter: |

260mm round or 6인치 x 6인치 square

|

360mm round or 8인치 x 8인치 square

|

Dimension (desktop version): |

302 mm 380 (w) x 307 (h) x 599 (d) mm |

402 mm 430 (w) x 310 (h) x 650 (d) mm |

Shipping weight: Shipping dimension: |

20 kgs 680 x 580 x 480 mm |

32 kgs 780 (w) x 620 (h) x 580 (d) mm |

Requirements Voltage: Power consumption: Max. current: Vacuum: Motor purge gas: Drain connection: |

100 - 120 VAC / 200 - 240 VAC |

100 - 120 VAC / 200 - 240 VAC |

| Specifications | POLOS 450 Advanced 스핀코터 |

|---|---|

프로그램수: 스텝: 회전수: 정밀도: 회전방향: 최대 가속도:Ramp up down가능 시간 설정 Free programmable outputs: 시스템 본체 재질: 챔버 재질l: Interface: External connection: 최대시료 사이즈 : Max. process chamber diameter: Dimension (desktop version): Shipping weight: Shipping dimension: Requirements Voltage: Power consumption: Max. current: Vacuum: Motor purge gas: Drain connection: |

Unlimited Unlimited 0-1,500 rpm ± 1rpm steps ± 0.1 rpm Clockwise, Counter clockwise and Puddle <1500 rpm/s depends on the load unlimited 3 dry relays, nominal switching capacity 0.5A /125 VAC - 0.3A / 60DC Natural Polypropylene (NPP) Natural Polypropylene (NPP) or High Chemical Resistant PTFE (TFM) Detachable, full-size touchscreen, glove-friendly, IP52, chemical resistant 1 USB Port in the controller 460 round and 350x350mm square substrates 502 mm 795 (w) x 638 (h) x 922 (d) mm 75 kgs 800 x 790 x 1180 mm 200 - 240 VAC 50/60 Hz Peak 1000W 10A -80 kPa (-24 inchHg), > 80 lpm. Tube OD Ø 8mm 20 - 50 kPa. Tube OD Ø 6mm 500lph 1,5” M-NPT |

Considering additional capability of standard unit such as USB backup, recipe cycling, PC software etc.

Measured without substrate, limitations may apply depending on chuck used and substrate specification.

POLOS 200/300/450 Advanced 스핀코터 옵셔널 악세사리

|

|

|---|---|

EBR (Edge Bead Removal) Auto Dispense Lines Full PTFE Dispense Vessel Automated injector line |

MegPie BSR (Back Side Rinse) The Sapphire MegPie is a single-wafer Megasonic transducer for cleaning and sonochemical processing. |

|

|

| Static Barrier Plate High Pressure Jet | Corrugated Drainhose, Drain tank andVacuum Pump connector In NPP, including connection to The vacuum pump is very quite and reliable.connect to the drainport. |

POLOS 600 - 1000 :대형 스핀코터

|

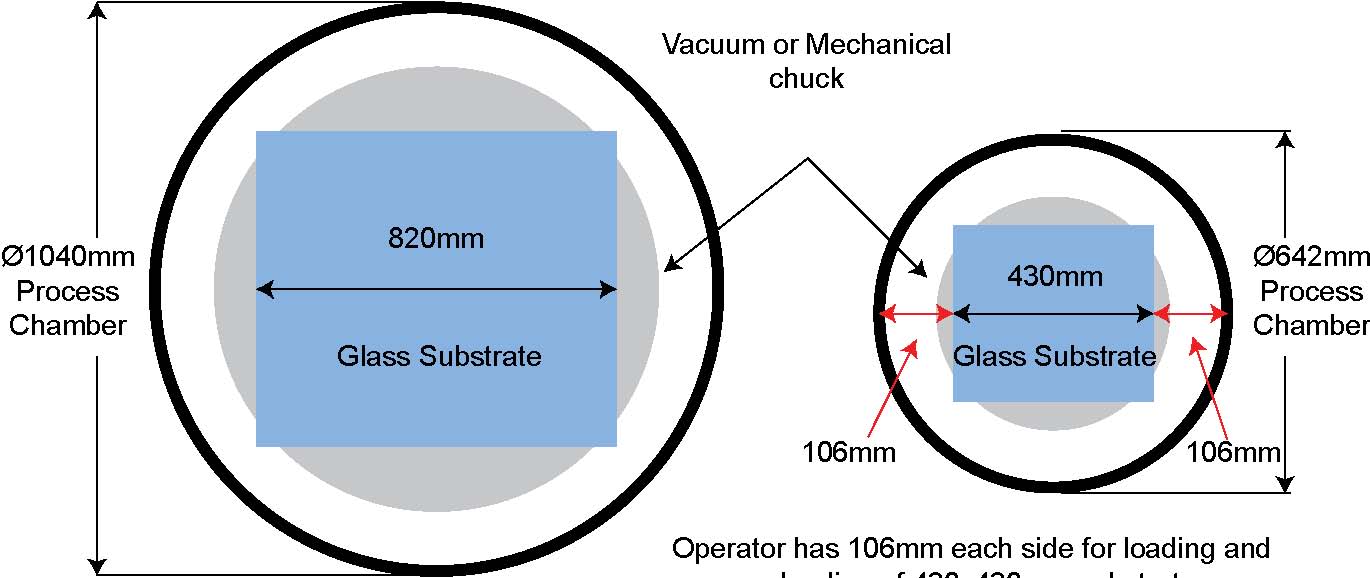

POLOS 1000 NPP POLOS 600 NPP 최대시료사이즈 :642 mm dia |

|---|---|

|

unloading of 430x430mm substrate |

스핀코터 응용작업

polos 스핀코터 응용작업.

-Megasonic MegPie와 special Lift-Off Fluid로 photoresist strip 이나 metal lift-off 작업 가능.

- Ozone in DIW (DiO3) providing an effective replacement for Piranha (H2SO4, H2O2) cleans.

-PTFE 버전 스핀코터로 다양한 스핀 프로세서작업 가능.

스핀 클리닝,에칭,코팅,디벨로핑(Cleaning Etching Coating Developing )

코팅(Coating)

|

스핀코팅은 얇은 폴리머막(나노메트릭,PDMS, blockcopolymers, etc.)을 도포하는데 아주 유용한 방법중의 하나로 사용되어 왔으며회전속도를 변화시킬때의 가속작업은 균일한 두께의 코팅막을 얻는데 중요합니다.일반적으로 스핀코팅은 1000RPM 이상에서는 쉽게 균일한 도포막을 얻을수 있습니다.

|

|---|

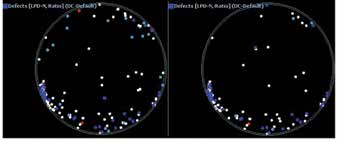

Example: Post-CMP Cleaning

|

After CMP often the surface is highly contaminated by slurry residues. Tests on 3’’ polished silicon wafer pressure a slurry containing 50nm colloidal silica particules showed that by using the POLOS Advanced with ZTop MegPie Megasonic Transducer, Highly diluted (2%) NH4OH is used to enhance electrostatic repulsion between particules and surface (control of Zeta potential) to avoid re-deposition and re-attachment. |

|---|

After CMP After megasonic cleaning

|

|

|---|---|

In our test case the Polos ZTop MegPie integration kit for Polos

Advanced 200mm was implemented. This MegPie kit allows you

to choose between 150 and 200mm active area, and is available in a Sapphire or Stainless Steel ZTop MegPie.

The Polos ZTop MegPie control is integrated into the software

of the Polos Advanced, allowing servocontrolled positioning of the MegPie, forward power, as well as monitor the reflected

power and control the temperature alarms. The distance to the substrate is monitored with an ultrasonic sensor.

Upon Megasonic cleaning using diluted NH4OH, excellent results are obtained.

Test report available at request.

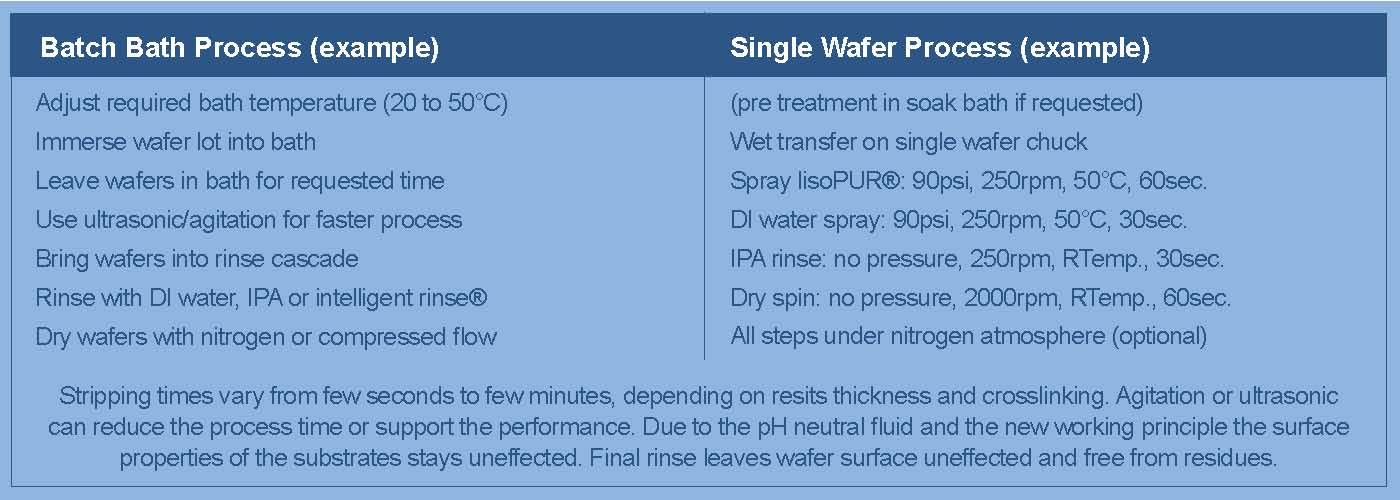

Example: Non-Hazardous Cleaning,

Photoresist Stripping and Metall Lift-Off

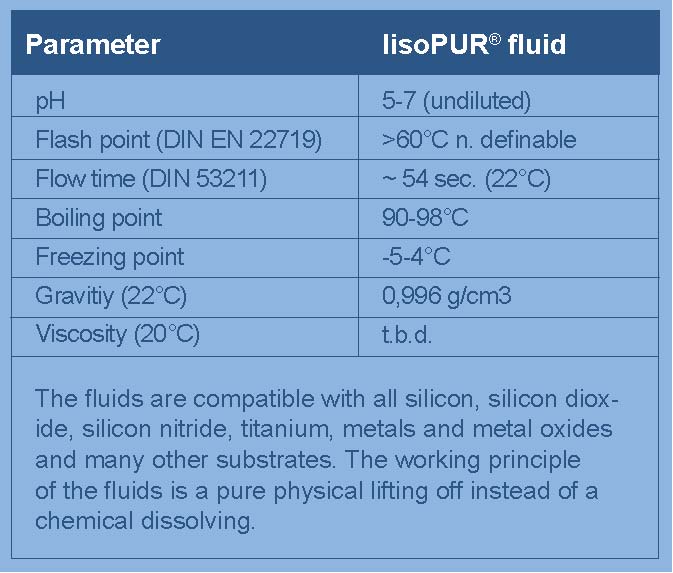

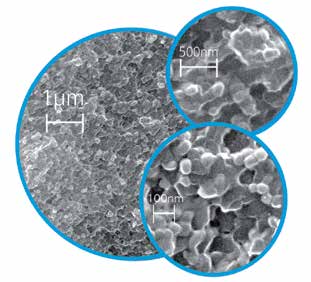

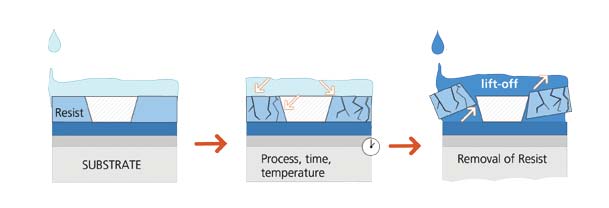

polos 스핀코팅은 offer water based intelligent fluids®

that use a non-disruptive, unique technology based on smart, gentle ingredients to enable new possibilities for innovative stripping and lift-off applications in microelectronics.The lisoPUR®

product family are liquid-liquid based fluids which form dynamic inner structures. The fluids are built up from dynamic and flexible plasmicells. The globular shapes of the fluid interact with each other and tend to change their forms within milliseconds (1,000 to 8,000 times per second).

Particle Free Application

Si sample

Pre processing

with phase fluid

74 defects

Si sample with phase

0.12-1.00μm

fluid and DI water rinse

Particle measurement (KLA Tencor SP2) indicates almost neutral particle behaviour after

cleaning with phase fluid and diluted SC1 short

Si reference

rinse. Use of the MegPie can reduce the process time or support the performance. Due to the pH FTIR characterisation of Si reference and sample neutral fluid and the new working principle the after fluid and water rinse off shows total surface surface properties of the substrates stays unefrecovery and absence of any residues. fected. Final rinse leaves wafer surface uneffect

ed and free from residues.

Physical Data Overview Intelligent fluids® are Enabler for Technology Advantages on Substrates

The character of the fluids reduces critical impacts

of the stripping process, such as surface

roughness, pattern collapse, insufficient wetability

and reduces process complexity.

TCO & Performance Advantages

The smart mode of action optimises process parameters like time, temperature, energy, consumption and/or bath life.

Ecological Advantages for Safe Use

Intelligent fluids® consist only of gentle ingredients

without hazardous potential. The waterbased

formulations are non flammable, pH neutral,

biodegradable, and can easily deactivated by

adding water.

Advantages of lisoPUR®

- Enables future semiconductor technology trends

- Reduced total costs of ownership

- Reduction of process steps er time

- Extraordinary stripping performance

- Sustainable process fluids (incl. recycling)

- Dermatologically tested (very good)

- Neutral pH range, non corrisive, non etching

- No substrate stress, corrosion or oxidation

- Smart but powerful formulations

Process Data for lisoPUR® waterbased Photoresist Stripper

| STEP 1 | STEP 2 | STEP 3 | STEP 4 |

| lisoPUR® stripper starts to | Creeping/fragmenting | Rinse-off (DI water, IPA, etc.) | Wafer drying at high velocity |

| penetrate and diffuse the | reduces adhesion forces | removes fragmented resist | spinning |

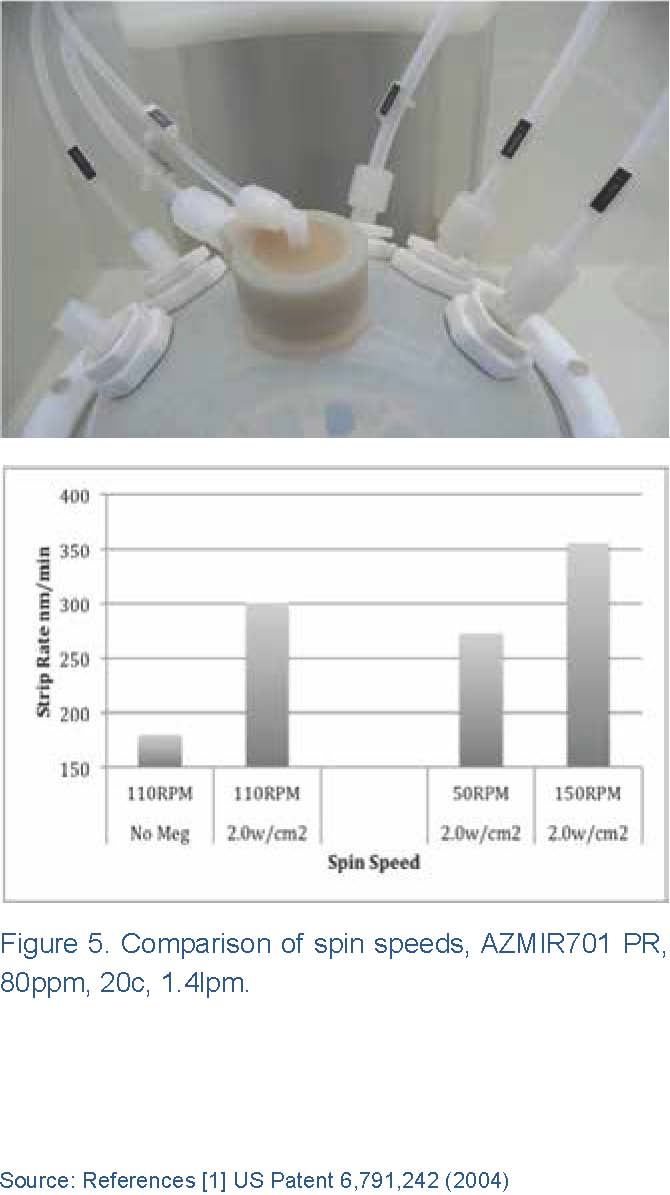

Example: Megasonic Enhanced Photoresist Strip with DiO3

Dissolved ozone in DIW (DiO3) provides an effective replacement for Piranha (H2SO4, H2O2) cleans. The fundamental chemistry of ozone based cleaning is due to direct and indirect reactions of ozone and oxygen radicals (the so-called radical pathway). Due to its high oxidation rate the radical path

way can accelerate the reaction. Megasonic energy can act as an initiator for the radical pathway. At

the same time, due to the creation of turbulence inside the boundary layer, the available ozone close to the surface is increased.

In a study by D. Dussault of ProSys and Jens Fittkau and Christiane Gottschalk of ASTeX GmbH, the authors show, that the combination of DiO3 and a uniform Megasonic energy field in a conventional single

|

wafer spinner significantly increases the strip rate of various positive PR coatings compared with DiO3 alone. They measure improvements in strip rate of over 65% (figure 5) Variations in spin speed (rpm), flow rate (lpm), and megasonic dosage (W/cm2) resulted in large effects on the measured strip rate. The POLOS Advanced 200 series allow for ±0,1rpm spin speed accuracy, and the user can easily program speed up to 12,000 rpm in 1 rpm steps. Up to 6 dispense lines can be automatically controlled. Measured without substrate, limitations may apply depending on chuck used and substrate specification |

|---|

Don Dussault , ProSys Inc, Jens Fittkau2 and Christiane Gottschalk, ASTeX GmbH

Example: Etching

Spin Etching as post-treatment after Wafer Thinning

Wafer thinning (back side grinding) is used in IC and MEMS fabrication in order to:

-Achieve a desired device thickness (ICs, MEMS)

-Ensure a specific thickness based on device functionality (MEMS)

-Reduce substrate series resistance in vertical devices (Power devices)

As a study by Dr. K. Gottfried of Fraunhofer ENAS by spin etching with HNO3/HF/CH3COOH on a POLOS Advanced Spin Station proved that wet etch, executed as spin etch, offered removal of 10 μm silicon, and is suitable to remove grinding induced substrate damages almost completely.

CH3COOH HF HNO3 DI water

The platform offers a comparatively simple, reasonably priced process setup. The process being much faster than CMP offered a high and tunable etch rate (much faster than CMP) and the ability to process grinded wafers direct without additional cleaning.

Standard features

Process applicable to 100mm, 150mm, and

200mm wafers with minimum conversion

time (less than 15 minutes)

Chemicals

KOH

HNO3/HF/CH3COOH (HNA)

Wafer rotation

Continuous wafer rotation

Puddle mode

Subpoints of “Dispense position and mode”

Fix position

Oscillating movement over a specific

distance (wafer diameter)

Spray dispense

Flush dispense

Depending on the chemicals used

Source: Fraunhofer ENAS-Dr. Knut Gottfried, Precise Bulk Silicon Wet Etching 2013

Spin Process Station

Based on the proven high quality POLOS Single Substrate Spin Processor, the modular design Spin Process Station provides excellent value for money: full plastic construction, with high-end components, compatible with any chemical environment in a modular set-up, suitable for your

specific requirement. An extremely versatile platform for a wide range of processes.

Multi-Process Chamber

The compact circular process chamber is constructed of solid polypropylene or ultra-pure PTFE, while the movable dispense arm, process tanks, and chemical supply lines are all

made of ultra-pure, seamless Teflon® (PFA or

PTFE). This entirely metal-free environment is suitable for a variety of aggressive media, and a multitude of processes. The sideway integrated dispense arm fully withdraws from the process chamber to avoid negative influence on process uniformity.

|

|

Modular Setup for a Wide Process Window in a Compact Footprint |

|---|

Value for money

Fully automatic, accurate and repeatable processing: Movable linear dispense arm:

- Freely programmable static, dynamic or oscillating chemical dispense

- High pressure and/or megasonic cleaning directly to any

point on the substrate. Static chemical dispense through a range of adjust adjustable nozzles in the domed lid.

Adjustable back-side spray arm.

General Features:

Heavy duty motor: programmable for 0 - 12,000 rpm.

-Spin Processor

Freely programmable processes:

- Sequentially programmable multiple dispense line- Manual Loading -Stepless programming of various flows within a process step - Flexible Processing from 150 up to 2,500 ml/min. For optional integrated mixing systems, the mixing rates of the various chemicals can be programmed per step.

Spin Process Station

|

Examples for a wide range of substrates and applications: Laboratory Glass, e.g. 76x26mm Pieces & Fragments Wafers: from 1” up to 12” |

|---|

Application Examples |

Application Examples: |

Application Examples: |

Optical Media |

|---|---|---|---|

SC1-SC2-DHF Clean-Rinse HF/HNO3 Etch Photo Resist Coat Edge Bead Removal (EBR) Puddle and/or Spray Developing Post CMP High -70°C KOH Etch with recirculation - Diced Wafer Clean (on Film Frame) Mask/FPD Glass Substrates: |

Coat-Develop, up to 20” Piranha (Etch) Clean up to 16” Solar Cells: 103, 125, 156 and 210mm square

|

Texturing: Alkaline or Acidic Porous Si Etch Oxide Etch (PSG RemovalCleaning Protective Layer Coating Film Frames: 4” up to 12”

|

Spin Process Stations are available in an 85cm, 1m40, 1m70 or 2m wide welded polypropylene enclosure with built-in integrated spin processor, containing separate pneumatic, electrical and chemical compartments. Chemical tanks, heaters/chillers, etc. are safely stored and easily accessible in a slide-out drawer. At the heart of each Spin Process Station is the POLOS Spin Processor proven technology. These rugged, reliable units deliver repeatable performance. Spin Process Stations offer a wide process window for your current and future requirements and are surprisingly affordable. |

Spin Process Station

|

Safety To protect users, the process chamber is automatically opened and the chuck is raised - presenting the substrate for easier and safer unloading. This eliminates any possible contact between the operator and possibly chemically contaminated surfaces. Both manual and au tomatic chamber rinse/flush sequences can be programmed, allowing all contaminated surfaces to easily be neutralized - even after a power failure. The automatic chemical supply system and the drain/extract / exhaust are integrated into the system to ensure fail-safe operation. Purged labyrinth seals, monitored safety interlocks, alarm sensors, vacuum monitoring, spin motor overload protection and emergency switch ensure the highest safety standards. |

Main options: -In-situ Z- axis chuck movement -Linear dispense arm, servo controlled -Multiple dispense lines & nozzles -Several chucks designs available -Highly responsive closed loop flow control system -In-situ chemical mixing -Heated chemical supply - Megasonic cleaning -High pressure jet -Teflon® process tanks or dispense vessels -Chemical reclaim, filtered chemical recirculation -Multiple drain outputs |

|---|

Other products

휴대용 박막측정 시스템

FR-pOrtable is a unique turn-key solution for accurate & precise optical characterization of transparent and semi-transparent single

films or stack of films.

With FR-pOrtable the user can perform reflectance measurements for films in the 350-1,000nm spectral range.

In just one click, we characterize thin & thick

transparent and semi-transparent films by analysing light reflection.

Get rid of power cables and large lab space requirements. Thanks to its unique design, FR-pOrtable draws power from the USB cable that is used for its control from the computer.

|

|---|

Equipped with: A) Hybrid integrated Incandescent-LED light source emitting at spectral range 350-2000nm and software controlled through embedded ymcontroller. B) FR-Monitor software for the control of the tool, data acquisition and data processing for calculation of C) Reference Samples: a) a silicon calibrated reflectance standard, b) a characterized area of SiO2/Si and c) a characterized area of Si3N4/SiO2/Si. D) Reflectance probe stage and holder for reflectance measurements of films: maximum sample size 180mm, irregular shape. Manual adjustment of measurement height up to 60mm. E) Optical probe for reflectance measurements. Transmitting light fibers 6x200ym, reflectance fiber 1x200ym, embedded in the tool The overall specifications of the quoted system are: Sample size: from1mmX1mm to 180mmX180mm. |

Easy, portable, with USB-Connection to your laptop

|

Polos Precision Bake Plate The Modular setup of this new Table Top Hotplate enables easy plate (chuck) exchange and upgradeable options, making this a versatile and affordable tool for R&D and Pilot Lines. The POLOS Hotplate is available for processing single or double substrates. A precision digital temperature controller enables adjustable temperature steps of 1°C up to 230°C. It is suitable for soft bake as well as hard bake processes, and curing of photo resist or epoxy or any other work requiring precise temperature control. Standard models for substrate sizes 150mm, 200mm and 500mm. |

|---|