SPIN 200i-ind 스핀코터(키보드 분리형)

싱글프로세스용 스핀코터

용도 :cleaning, drying, coating, developing and/or etching of up to Ø260mm substrates:

|

|

|

- 가능사이즈: up to Ø260mm wafer,150mm x 150mm

- 재질 : Full 플래스틱 하우징(NPP) -옵션으로 테플론 재질 선택가능

- RPM :0-12,000RPM,

- Accuracy :+ - 1RPM, APT German DC Servo Motor

- Step :Unlimited Step &Memory

- Acceleration / Deceleration : 1-30,000rpm/sec, step별로 설정가능

- 회전방향 변동가능 : (CW, CCW, puddling)

- Time : 0.1~99999sec

- 컬러터치스크린을 통한 쉬운 단계별 메모리 프로그램 가능

- 글로브 박스내 설치가 용이한 최소형 사이즈 : 380mm(W) x 307mm(H) x559(D) mm :

키패드분리시 : 380mm(W) x 307mm(H) x400mm(D)-키보드분리형

- Vacuum On/Off

- 3 Programmable Dry Contacts: for automated control of Dispense unit, Nitrogen diffuser, etc.

- 고정밀 독일제 DC 서보 모터 사용 :최고의 Coating Thickness Uniformaty 가능

- Digitally controlled Motor with digital incremental speed signal feed back - 투명한 뚜껑및 :중앙에 디스펜싱용 시린지 홀더용 Hall :수동 디스펜싱 or오토디스펜싱(추가키트 필요) 가능

- Automatic safety lid lock with sensor interlock

- 분리 가능한 컨트롤러(컨트롤패드)

- N2 diffuser for N2 purge during process

- Structured and password protected recipe

storage for easy and safe management

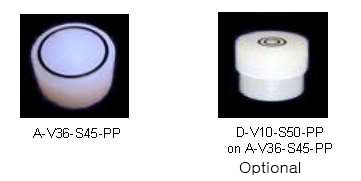

포함 : standard Vacuum Chuck A-V87-S96-PP-HD Ø96mm for up to Ø8“ wafers.

Drain connection 1” male NPT

|

|

|